I was looking to solve a clearance issue between the King coilovers and the new Tuff Country spindles, to strengthen the front end and maybe even get a little more travel. The new AllPro 1 inch Uniball upper control arms were the ticket. The new arms are slightly longer than the factory ones and move the top of the spindle out 3/8 inch. I was hoping that this would solve the clearance issue. Did it? You will just have to read on and find out!

To see all pictures of the install click HERE.

This is one of the problems I am looking to solve. The Tuff Country spindle (red arrow) and the upper control arm (yellow arrow) come into contact with the King coilover when the suspension is at full droop. The new AllPro arms are 3/8 inch longer than the stock arms, so they will move top of the spindle out slightly and hopefully solve this problem.

If you have the stock coil and strut assembly and the Tuff Country lift, this is not a problem.

A few taps later and it was coming out. I suspect that the fact that the front end parts are only a few months old helped! If they have been in a while, they may be quite a bit harder to remove.

I did a practice run on the set of factory spindles and ball joints that came on my 2001 just to see how hard they would be to remove. To see that write-up, click HERE.

With the ball joints out, it was time to install the slug adapter for the new arms.

This is where we ran into a slight problem. The slug adapter runs very slightly smaller than the stock ball joint. The Tuff Country spindles ball joint opening runs very slightly larger than the factory spindles. The combination of the two made it so that the AllPro slug adapters slip into the Tuff Country spindles by hand and spin.

If you are replacing the ball joints in the Tuff Country spindles it is not a problem.

If you are using the factory spindles with the AllPro slug adapters, it is not a problem.

We called Eric at Donal Machine and he made us a new set of slug adapters for the Tuff Country spindles. Eric is the one who makes the TTORA scrape plates.

The next step is to install the slug adapter into ball joint opening. Since it is a press fit, I made up a simple puller to install the new slug adapters. It consists of a piece of pipe, a longer bolt and nut, and a piece of metal plate. You put the bolt through the plate and then through the pipe. The pipe is positioned over the top of the ball joint opening and the bolt is passed through the slug adapter. The nut is put onto the bolt and then you tighten the bolt while holding the nut and the slug is pulled into the opening.

Here you can see the home made puller next to one of the slug adapters.

I removed the battery and tray to get easier access and good pictures. You might be able to get away with not removing the battery. The three small 10mm bolts (green arrows) were removed and the wires and sensor were moved out of the way.

The lower of the three bolts is below the sensor and not visible in this picture.

When I was putting the third washer on the inside of the arm, it was a tight fit. I used a screwdriver to get it started then a small rubber mallet to get it into place for the bolt to go through.

Here you can see all the 4 washers in place. One on each side of each end of the arm. Torque the upper control arm bolt and nut to 90 foot pounds. I used threadlocker as well.

Once the arm is in place, You can bolt the arm to the slug adapter in the spindle. Torque the bolt to 80-90 foot pounds.

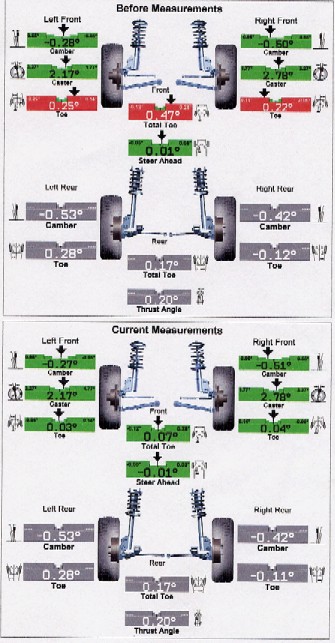

Here is the final alignment check that I did (about 3 miles before I tore the end apart!). They had some problems getting everything where they wanted it to be, but overall it was OK.

You can see that the left and right front toe is still out, but the total toe is fine.

This was the third alignment on the Tuff Country lift. We wanted to keep an eye on it and see if it was holding the alignment after some hard off-roading. I am happy to say that it has!

9-3-2004